Innovative Silk Bioink for 3D Bioprinted Bone Marrow Tissue Models

Combining silk with bioprinting to recreate human bone marrow environments

The human body possesses a remarkable ability to respond to injuries by producing platelets that facilitate blood clotting. This intricate process is led by giant cells called megakaryocytes that reside in the bone marrow, inside our bones.

However, the natural production of platelets does not meet the demand for transfusions required to treat millions of people suffering from blood diseases, viral infections, or chemotherapy.

Today, the primary source of platelets is from healthy donors. However, the rising need for platelet units, coupled with their remarkably brief shelf life of approximately five days, frequently leads to shortages in platelet supply. Complications arise, particularly during periods of low donation rates, such as summer, or in times of public health emergencies like pandemics. Pharmacologic therapeutic options may be valuable alternatives, though the choice of the best treatment regime is challenging.

A functionalized bioink that mimics the softness of human bone marrow

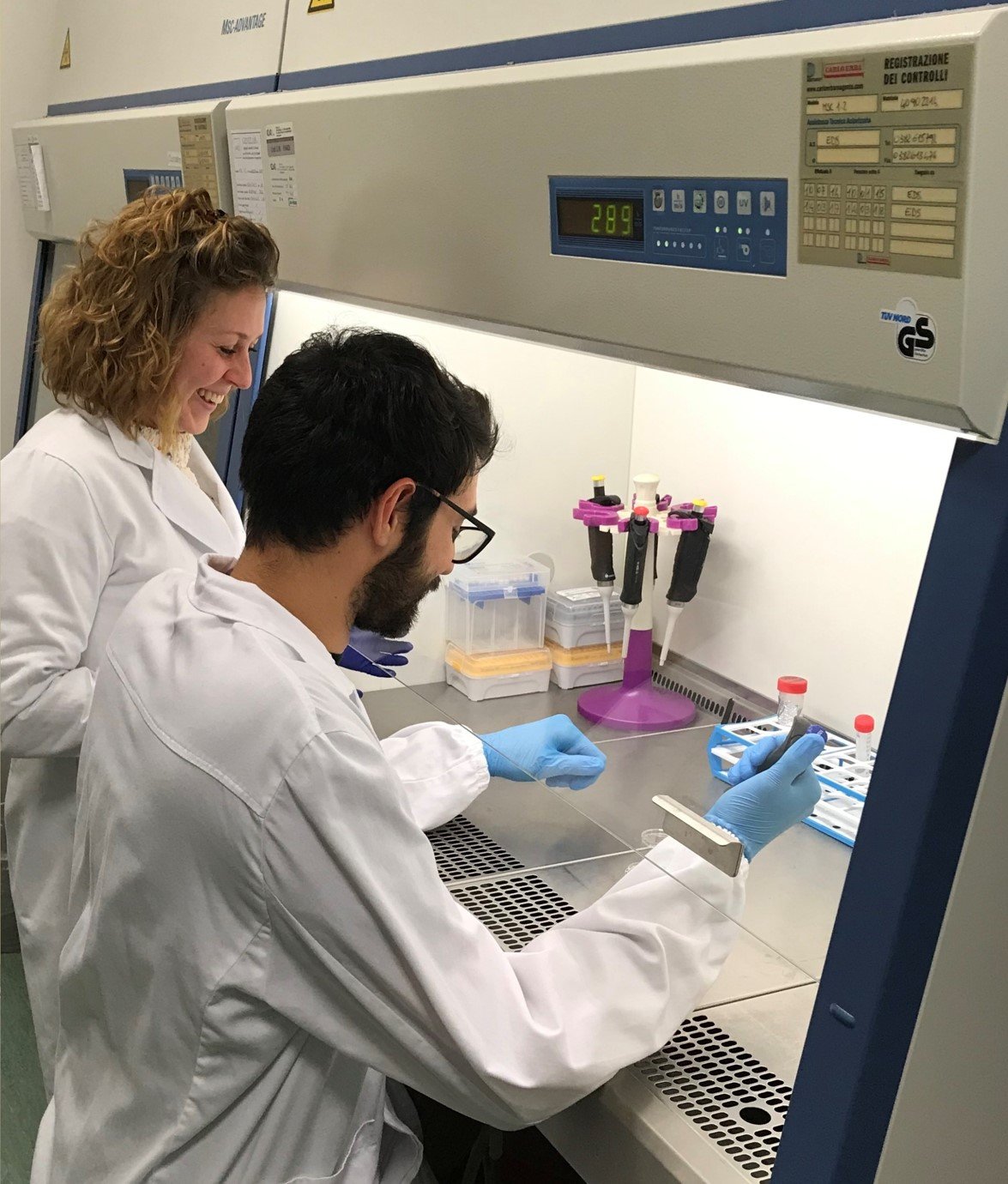

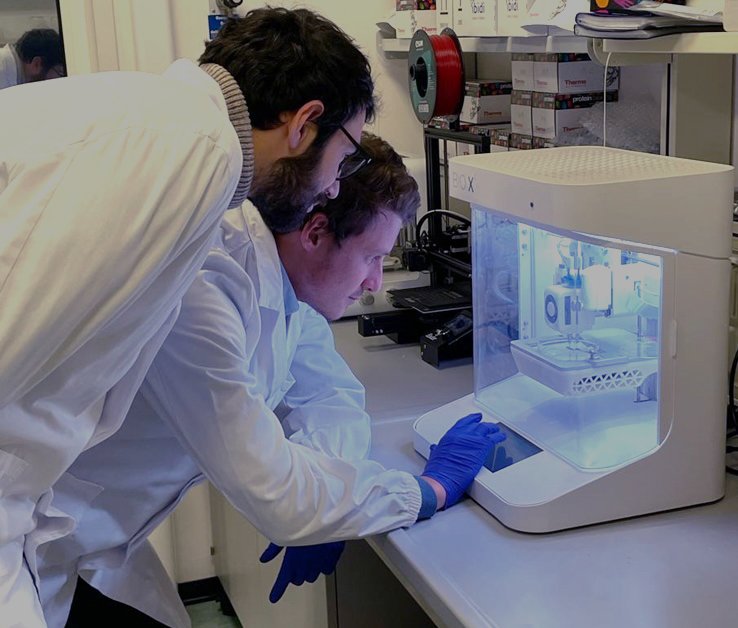

Prof. Alessandra Balduini and her team at the University of Pavia are taking this challenge head-on by initiating the EIC Transition SILKink project 101113073, which aims to produce a groundbreaking platform that combines the use of natural silk and 3D bioprinting to recreate the environment of the human bone marrow where platelets are produced. Researchers think that they can program lab-grown megakaryocytes to believe they are inside the human body and provide a sensitive system for ex vivo screening of new therapeutics directly on patients’ megakaryocytes, thus leading to the choice of the best therapeutic course and ultimately to improvements in clinical care.

The project is led by the University of Pavia in Italy, collaborating with CELLINK Bioprinting. Partner Catalyze-Group will lend its commercial expertise to develop an optimal market access strategy for SILKink.

Creating a cutting-edge bone marrow model

For over 15 years, we have researched the mechanisms of platelet production in the human bone marrow, and the clinical aspects of human diseases associated with platelet and clotting processes. Dr. Balduini’s team developed an early 3D model of silk-bone marrow which served as the project’s foundation and starting point. Although the existing model was functional, it lacked the appropriate stiffness. The team goal was to standardize the model to allow usage for drug testing applications and personalized medicine.

The team turned to bioprinting to solve these challenges. Before any printing occurred, the team first needed to identify and develop a bioink that could be used to produce the bone marrow model. The bioink needed to be soft enough to mimic the softness of bone marrow.

Not all biomaterials are suitable for platelets, as some hinder megakaryocytes from generating platelets or lead to premature exhaustion of newly formed platelets. Furthermore, the 3D structure needs to consist of extracellular components to support the differentiation of megakaryocytes, without adversely activating the platelets.

This project has received funding from the European Union’s Horizon Europe research and innovation programme under grant number 101113073. Views and opinions expressed are those of the author(s) only and do not necessarily reflect those of the European Union or European Innovation Council. Neither the European Union nor the granting authority can be held responsible for them.